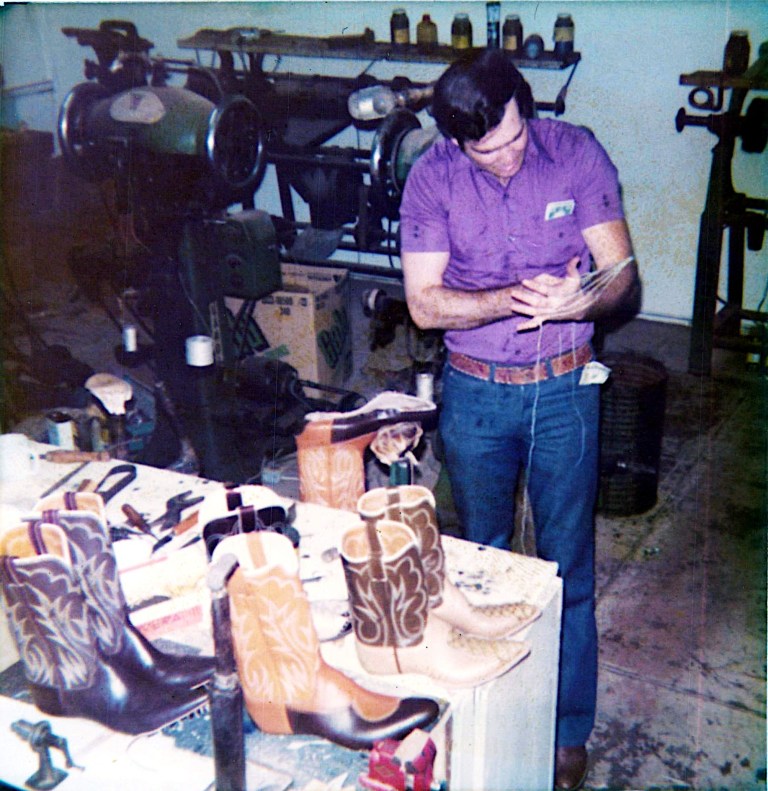

Some folks might think that Alan Bell picked the wrong profession. Instead of making custom cowboy boots, which Bell has done for 40-plus years out of a one-time barbershop in Abilene, Texas, he could’ve been a stand-up comedian or a TV talk-show host. Imagine Johnny Carson (if you remember Johnny Carson) with a deep Texas drawl.

Here’s Bell:

On his hometown of Blackwell, Texas – “It’s so small that the city limits sign is on one board.”

On the pair of boots he’s wearing – “I’m wearin’ an ol’ worn-out pair of boots that I should’ve thrown in the trash. I need boots worse than any customer that I know.”

On his shop – “It looks like we’re a family of vagabonds.”

On his career – “I’m terrible at braggin’ about myself. An old bootmaker told me one time that braggin’ is a very strange disease. It makes everyone sick except the one who’s afflicted with it.”

On what he would do if he weren’t a bootmaker – “I’ve forgotten everything else I’ve ever known, so I don’t know anything else.”

On second thought, Bell found the right career path when, after an apprenticeship with Tex Robin, Bell opened Bell Custom Made Boots in 1977. Yet he almost became a saddlemaker.

His future father-in-law, Paul Calhoun, a saddlemaker out of San Saba, Texas, had died and Bell wanted one of Calhoun’s stock saddles “to remember him by,” so he bought one and took it to Abilene saddlemaker Bill Barton to have Bell’s name stamped inside the saddle.

“We just hit it off,” says Bell, 71. “Just went together like peas and carrots and [Barton] told me, ‘Just come on in any time, young man,’ and that’s what I did.”

A horse wreck had seriously injured Bell. “Busted up my right leg and my right forearm,” he recalls. “I was in a cast from my toes and up to my butt – I called it my aspirin bottle – I was crimpin’ around, laid up pretty bad. Back in those days, we only had two TV channels here in Abilene, couldn’t hardly get either one of them, and I believe I read every book in the Abilene Public Library twice, and the only TV, especially in the mornings, was the soap opera Days of Our Lives, and, that like to ’ve drove me crazy.”

“I apologized to Bill for keep comin’ back to the shop, but said, ‘I’ll tell you what, Mr. Barton, if I hear ‘Like sands through the hourglass, these are the days of our lives,’ I’m gonna lose it.’”

Eventually, Barton put Bell to work.

“One day he threw me a belt he had tooled up. ‘Son,’ he said, ‘if you’re gonna hang around here, I’m gonna put you to work. Buck-stitch this belt for me.’ Well, I didn’t know how to buck-stitch a belt, but I soon learned.”

That was in 1973, and Bell began learning how to repair boots and make saddles.

“I can still make a saddle, I believe,” Bell says. “But I can’t guarantee how they’d look because I haven’t touched one in about 44 years. It may have two horns and two cantles, I don’t know. I love to do both, but I found out right quick makin’ saddles and boots at the same time, you couldn’t give the attention to either one of them that they deserve. I just went with boots.”

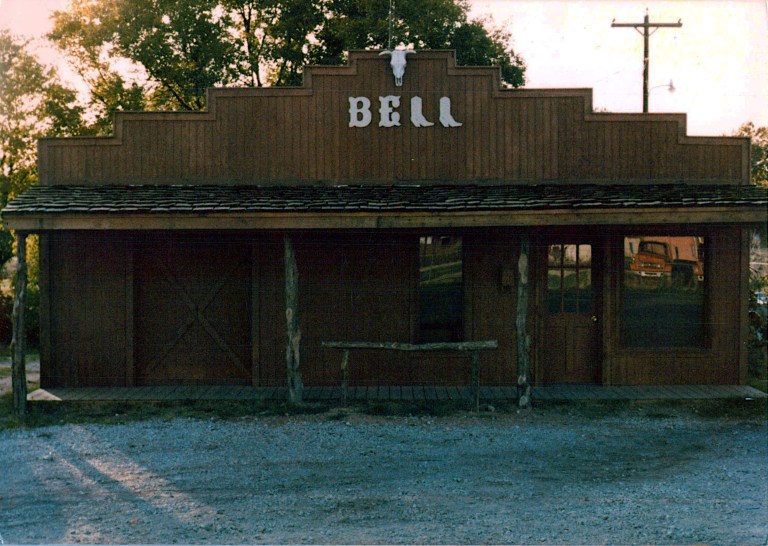

After learning the trade from Robin, Bell opened his own shop in Abilene just around the corner from another custom bootmaker, James Leddy, who also made boots in a former barbershop.

Leddy was already established as a bootmaker in Abilene, having started on his own in the 1960s. He also hailed from a bootmaking family. A nephew of iconic Texas bootmaker M.L. Leddy, James Leddy began working for his father, Wilson Leddy, at age 12. By the time Bell arrived, James Leddy’s customers included singers George Jones, Jerry Lee Lewis and Buck Owens.

“James had his bunch, his clientele, and I developed mine and never the two shall twain,” Bell says. “You’d think we’d be at each other’s throats.”

Instead, the two became not only allies, but steadfast friends.

“When I put in, I didn’t have a crimp break, for instance,” Bell says. “I didn’t have a top turner. Well, James had a crimp break and a top turner he wasn’t usin’ and he said come get that damned thing and use it. I said, ‘Let me buy it.’ He wouldn’t take money for it. James always called me Mr. Bell – he’s 10 years my senior. He said, ‘You take this top turner and crimp break and you use it.’ That’s just the kind of man he was. He said, ‘I tell you what, Mr. Bell, if you die first, I get them back. If I die first, they’re yours.’ So in 2003, that top turner and crimp break became mine. I use them all the time.”

Bell’s tone changes.

“James was a good a friend as I ever had in my life. I can’t say enough about him. I’ve got four brothers, and I don’t have a brother I thought anymore of than I thought of James Leddy.”

How many boots has Bell made over the years?

“All the old-timers always told me this when I was startin’ out: ‘Don’t count how many orders you make till you get out of the business because that’s bad luck.’ I just haven’t counted them up. Quite a few.”

Starting price? “I don’t go there either, because soon as you tell somebody…well, do you remember that show Sanford and Son? When Sanford would get upset and grab his heart and say, ‘Elizabeth’? Well, when you tell somebody what you’re startin’ at, you’ve just about eliminated him. Of course, you’ve got to settle on a price. Like the old bootmaker told me one time, ‘That’s where friendship ceases.’”

The comedy act has returned. But when it comes time to make boots, Bell’s dead serious.

His wife, Pauline, does all the top-stitching. “It took her almost three years before I’d trust her to stitch tops,” Bell says, but Bell insists on doing most of the work himself. “The more people you have workin’ on that boot, the less quality you’re gonna have.”

That’s especially true when it comes to measuring.

“I insist on measurin’ their feet,” Bell says. “A lot of people, even some of the bigger custom bootmakers, have someone measure their feet and then they have the fitter to fit the last. I’ve always felt, and am a stickler for this as well, that the person who measures the feet should be the one who fits that last.”

Bell also understands that “a fit to one person is not necessarily a fit to another.”

“I always told my oldest brother, ‘Don’t tell nobody who made your boots, son, because the only place you want that boot to touch your feet is on the bottom.’ He wanted a real easy-to-get-on boot. In the evenin’ when he’d get off work, he’d just want to shake his foot a little bit and they’d drop off.”

“I have some customers, if they can’t get them on without boot hooks and stompin’ all over this shop, with blood vessels poppin’ out on their forehead and sweatin’, they’re too big.”

“That’s what makes it so important to me that the person who measures that person’s feet, also does the last. All this comes up – I call it pickin’ their brain – durin’ the time that you’re tryin’ to determine how this person wants those boots to fit. I don’t give a damn what kind of boots they are, how much they cost, what kind of material they’re made of – if they don’t fit, they ain’t worth a hatful of ralph. Every boot I’ve ever made, [the customers have] all been in this shop for me to measure. Two things you’ve gotta measure, and that’s their feet and their head.”

Delivery of a pair of Bell boots takes about a year and a half these days. His favorite leather to work with? “That’s a hard question. My favorite leather, as far as wear-ability, lightweight breathin’ and toughness and shine, is ostrich. It’s just hard to beat. And another little add-on. No one has to ask you, ‘What’re those boots made of?’”

And the toughest part about making a cowboy boot?

“I don’t know. I haven’t learned that yet.”

Yes, comedy hour has returned to Bell Custom Made Boots. For live performances, visit the boot store in an old barbershop that looks like it was built in 1927 (which it was) on North Treadway Boulevard, in Abilene, Texas.

And don’t worry about the mess.

“I know where every piece of paper, every tool, every last, every piece of leather in this shop is,” Bell says.

This article originally appeared on Shoptalk Magazine and is published here with permission.

Find more articles in our section on Tack & Farm.