by Nikki Alvin-Smith for Horizon Structures

Why should you worry about the pitch of your horse barn roof? There is much more importance to roof pitch and roof materials and shapes than meets the eye.

Why should you worry about the pitch of your horse barn roof? The steepness or angle of the roof of any building certainly makes a difference to its overall presence, aesthetic appeal and the amount of interior space under its umbrella, but there is much more importance to roof pitch and roof materials and shapes than meets the eye.

The steepness of a roof is described in mathematical terms. Pitch is commonly referred to in the building trade as a ratio. The ratio describes the number of inch(es) rise per horizontal foot. It is also sometimes referred to as the angle in degrees its surface deviates from the horizontal.

Thus, a flat roof will be the only roof that has a zero pitch while the alpine style A-frame roof that reaches the ground is the other extreme in regard to roof pitch.

The steeper the roof the harder it will be to install and to replace. The use of manlifts or special scaffolding is often necessary for safety during roof installation and repair.

There are many other pros and cons of different pitch ratios, and when it comes to the construction process extensive rules and regulations are involved that govern the safety of the structure. We’ve all seen photos of roof collapses during snowstorms, or high winds lifting roofs off buildings entirely. Generally, these incidents occur as a result of faulty design where ordinances were not followed and the downward force of the weight of ice and snow on the roof overwhelms the roof’s supporting structure.

In extreme circumstances even the best constructed and well-designed roof can fail, particularly if high winds move snow across the roof and it accumulates unevenly on the surface.

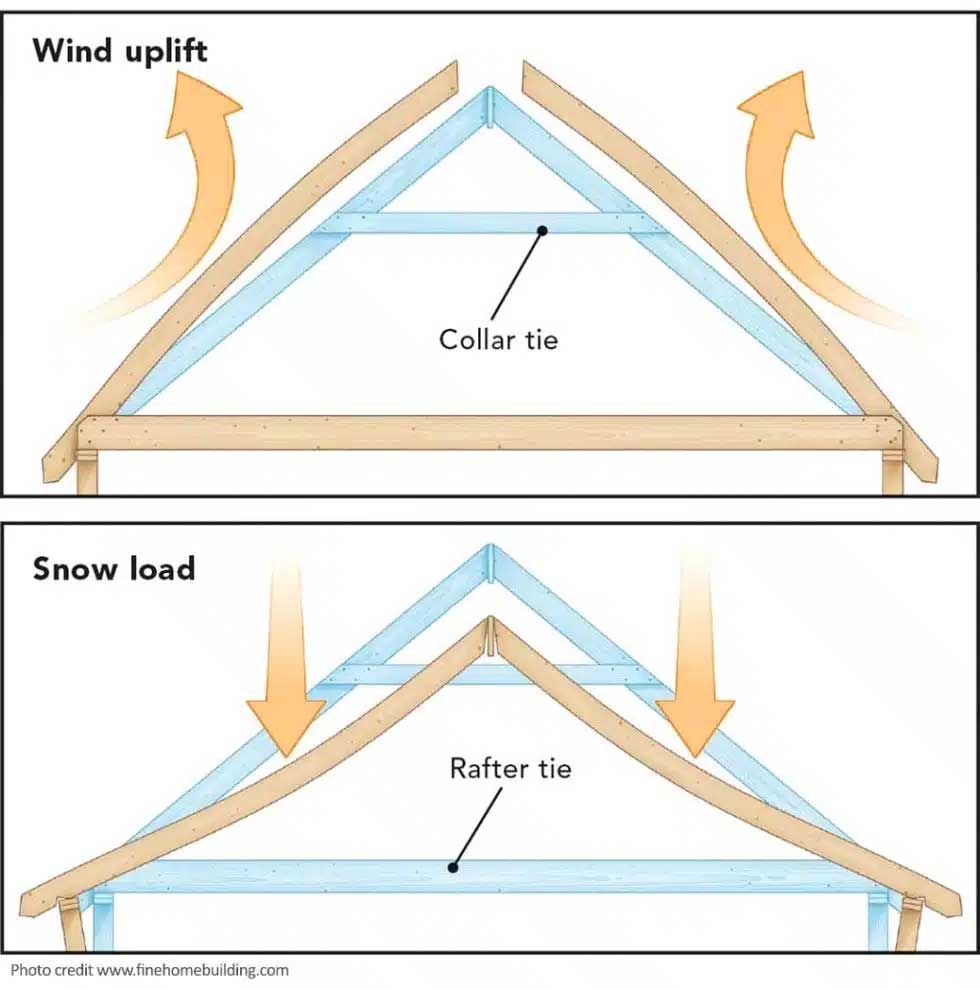

A roof needs to be able to withstand sustained high winds. Various ratings apply to shingle types and designs, and sheathing of the roof needs to be properly affixed to the main substructure of the building to avoid uplift. The use of collar ties in the upper third of the roof space can help the roof resists uplift. While rafter ties (horizontal framing members) installed on the lower third of the roof space help prevent an outward force on exterior walls. The appropriately rated and sized metal plates, hurricane ties, rafter ties, bolts and nails as well as their proper placement is essential to the permanence of the roof.

Open sided buildings will always be vulnerable to wind uplift, but all buildings are subject to this dynamic suction process that literally lifts the roof off the structure. It occurs where winds blowing parallel to the roof cause air pressure above the roof to be lower than that below it. A veritable Wizard of Oz situation!

Many rural communities do not require any type of building permit for agricultural use structures. This makes it easy for construction companies to overlook the mathematics of roof snow loads in the region, or to provide roof installation methods that offer hurricane protection.

How Well Does the Roof Do Its Job?

Beyond the obvious job the roof does of providing protection for the interior of the building from snow and rain, its ability to shed snow load and rain effectively rather than allow standing water or snow to gather on its surface causing water leaks is monumentally affected by its shape, its pitch, and the materials from which it is constructed. A metal roof will shed both snow and rain better than a shingle roof and thus usually requires less pitch to accommodate the snow and rain load requirements.

The roof also needs to offer good ventilation for the interior of the structure. This is usually accomplished by installing roof ridge vents or gable end soffits and/or cupolas. Mechanical aid in the form of fans is sometimes installed to improve airflow within the building.

Insulation Makes a Difference

The underside of the sheathing of the roof is also something to consider. The addition of a layer of insulation beneath the roof sheathing will not only mitigate the noise of heavy rain or hail on a tin roof insulation, but it will also prevent condensation from a metal roof.

Aside from the moist damp environment that condensation can create, the constant dripping of water onto hay supplies can cause mold to form and render the forage risky to feed, while water that drips from the roof into stalls or aisleways can make rubber mats slippery and unsafe.

An insulated roof will also help prevent ice dams forming on the roof during the daily freeze/thaw cycle in snowy regions.

Metal roof barns that are located in hot climates are subject to heat radiating to the interior of the building. A roof should deflect the heat of the sun during extreme high temperatures and color as well as materials used to clad both the surface and underside of the roof should be carefully considered.

The addition of plastic panels in the roof or skylights can add light to the interior of the structure and provide benefits of warmth in colder climates as well as diminish energy costs for lighting and heating the barn.

The use of drainpipes and a guttering system greatly enhances the functionality of a roof in regard to its ability to shed water and move it away from the foundation of the building.

How Strong Is the Roof?

The size and strength of the substructure that supports the roof, as well as the method by which it is attached to the framed members of the sidewalls is also an important consideration. Between suction from wind uplift, aspiration of water off the roof to the underside of the eaves and standing snow/ice or water load the rafter/truss system necessarily requires a well-engineered design.

Different roof styles offer various pluses and minuses when it comes to their ability to withstand wind (the hip roof is considered superior to other styles in this regard), and to shed water and snow.

The wider the span of the roof the heavier duty the support system, whether trusses or rafter design, will need to be. This is why steel trusses are often used in large agricultural buildings such as indoor arenas versus wood materials. Trusses are stronger than rafter construction and they transfer the weight or load of the roof to the outer walls of the structure allowing the interior to be free of posts/pillar or interior wall support.

Should You Choose a Shingle and Metal Roof?

There are many other factors to think about when choosing your roof.

The fire rating of a roof can be an element in how much insurance you’ll pay. Unrated roof coverings offer the worst fire rating and Class A, B or C, with A being the highest rating, can save you money as well as give you better peace of mind.

Shingle roofs may be made of asphalt or fiberglass, with asphalt having a worse fire rating but a better choice for durability in cold climates and for its ability to withstand high winds. But shingles can crack, corrode and shrink over time and are not as durable as a metal roof.

Application of a layer of ice and water shield over the sheathing layer of a shingle roof underneath the felt or tar paper can notably extend its durability. This is especially useful in snowy regions where ice dams may result from blocked gutters and spouts, lack of roof insulation or lack of airflow under the soffits of the roof.

A metal roof can offer good fire resistance and energy efficiency and can last up to 50 years. Additionally, a metal roof can better withstand high wind than a shingle roof and will require less maintenance over its lifespan.

Metal roofs also vary significantly in quality and thickness. A thicker metal roof is not necessarily better than a thinner one, it all depends on the decimal thickness of the aluminum or steel being used and whether that number includes the paint layer or not, as well as what the tolerance of the steel is as defined by the manufacturer.

Metal roofs that are manufactured of poorer quality materials will chalk over time and become unsightly requiring repair. This is due to a poor method of paint application to the bare metal or the use of substandard quality paint.

Adverse elements to all roof materials include chemicals and pollutants in the atmosphere and of course water. These elements can break down the pigment in the paint causing it to fade.

Take Home Message

When you are considering a new barn build don’t be shy to ask questions about how these facets are managed in the design you choose.

While steeper roofs will better shed snow and ice than a low-profile roof, and metal roofs shed water better than fiberglass or asphalt shingle depending on the appropriate pitch, there are many construction factors to review that ensure you are comparing ‘apples to apples’ when obtaining your quotation for a new horse barn.

This article originally appeared on Horizon Structures and is published here with permission.

You can find more informative articles in our section on Tack & Farm.