by Danna Burns-Shaw

Texas is known for many things: The Alamo, BBQ, Football, Black Gold-Texas Tea, Size (everything is bigger in Texas), Texas Longhorn, Texas Star, Chili, Hot Summers, and of course their slogan, “Don’t Mess with Texas.” Texas will claim that the first American cowboy boots were made in Texas, by H. J. “Daddy Joe” Justin in Spanish Fort, Texas. Folks from Kansas will argue the first cowboy boots were built by Charles Hyer, of Hyer Brothers Boots, in Olathe, Kansas.

Both historic entrepreneurs began their successful boot building operations in the 1870’s, Charles Hyer in 1875 and H.J. Justin in 1879. While Kansas may have been first by a few years, Texas has endured as the cowboy boot-making capital of the world. To understand the Fenoglio Boot Company in Nocona, Texas, it helps to know a little bit about the history of boot making in Texas.

BOOT MAKING TRADITION & HERITAGE

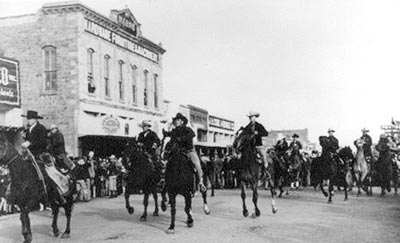

In a few years’ time, word had spread about the quality of cowboy boots being made by Justin Boots. With his business growing, Daddy Joe relocated a few miles south to the booming town of Nocona, Texas. The newly established railroad depot would mean a larger market of potential customers and a better connection to Fort Worth, with its stockyards and leather tanneries, which his business would need to meet the growing demand for his boots.

As Daddy Joe’s operation grew from his vision and leathered hands, Justin Boots became established as one of the earliest innovators of the modern Texas boot style. By the 1920s, Daddy Joe’s sons had taken over the business and against the wishes of his daughter, Enid, they decided to move Justin Boots to Fort Worth – to be closer to the masses and the stockyards, where leather and cowboys were plentiful. Enid stayed behind for a good reason.

The boot-making tradition in Nocona might have died that year when the Justin boys took their boot company away, had it not been for their strong-willed and enterprising sister, known by all who admired her as Miss Enid. She was an early feminist entrepreneur, who decided to keep the family business alive in Nocona. Despite the discouragement of her brothers, she believed it was her daddy’s wish that the boot company always remain in Nocona, a town that had been good to their family from the beginning. She launched the Nocona Boot Company in direct competition with her brothers in 1925. Over the next 80 years, the company grew and prospered under her leadership. Through wars and the cowboy craze of the mid-century, by the late-20th century (thanks to their quality and attractive styling), Nocona boots had become one of the most famous and respected of the Texas boot brands.

But times were changing, and though the Texas boot industry had weathered many ups and downs during its 100+years, tastes were changing and that meant lower boot sales. Outsourcing was beginning to put its pressure on the once venerable U.S. companies, and with Miss Enid’s death in 1990, it looked as though the town’s boot-making days and fame as a leather-goods hub were numbered.

Ironically, Justin Industries bought out the Nocona brand and in 1999, they closed down the sprawling art deco-inspired factory that Miss Enid had built. They moved the boot production to Mexico, which many in Nocona felt was sacrilegious – a Texas boot should be made in Texas, not in Mexico or China. That was another tradition that began there; a tradition that a few skilled bootmakers, who were left without a job when the boot company closed down, decided to keep alive.

FENOGLIO BOOT CO.

In 2001, a handful of seasoned boot makers in Nocona and a few new faces bent on keeping the business going, launched the Montague Boot Company. They opened their factory in the same brick building off Main Street where Enid Justin had started her famous boot business in 1925. From the outset, this new boot company competed with the giants of the boot industry, who had seen their operations grow immensely by outsourcing boot production to foreign countries.

But, that was not the business model used in Nocona, Texas, by the likes of Daddy Joe, Miss Enid and all the boot makers who called the town home for the past 150 years. The small group of men and women persevered in building boots the traditional way, and though theirs was a small operation through the mid-2000s, they were able to keep the boot-making tradition alive. Then another famous Nocona family, the Fenoglios–whose relatives had first settled this land back in 1886, took the reins and charted new and exciting courses in both traditional and modern boot making. The Fenoglio Boot Co. is fast becoming a brand that not only locals, but all Texans and foreigners alike value for the fine materials and workmanship. The finest in Texas boots are once again being made in Nocona, Texas…the right way.

Today, the Fenoglio Boot Co. continues to employ skilled bootmakers, who take pride in making high-quality boots to last a lifetime, in the time-tested, traditional ways. This is a small operation (by big boot corporation standards) and that’s just fine with the boot makers in Nocona, some of whom have been crafting boots for over 40 years. The only standards that the Fenoglio Boot Co. abides by are to build the highest of quality, truly Texas-made boots, with full-leather construction and traditional materials like lemonwood pegs and stacked, leather heels – the way they were intended to be made. These are big boots to fill, but the Fenoglios and their boot-making family truly believe in living up to the company motto: There’s nothing finer than Fenoglio.

Caiden (3rd Generation) has big dreams for the Fenoglio Boot Co., that they become the largest employer in the county, outside of the school system. They have plans to add on to their current 20,000-square-foot factory and to build a new warehouse. The Fenoglios own an outlet store (The Boot Store of Nocona), where you can pick up a pair of boots, western clothing and gifts.

Fenoglio is truly a family business; they are hands-on with every aspect of their business. They do not currently have a sales or design team; they use a direct sales approach and currently build a private label for the largest, independent western retailer in the country, Cavendars. Fenoglio is the largest, independently-owned U.S. western boot manufacturer, Caiden said, stating that the “big guys” outsource many of their boots from Mexico and China. Fenoglio is 100 percent built in Nocona, Texas, a small town with a great history of fine boot making.

Q. and A. with Caiden, grandson of the founder of Fenoglio Boot Co.

Can you describe the process of making a pair of boots, from the first step to the final?

A boot starts with finished hides, meaning the tanning, dying, distressing, etc., of the leather is done before we receive the hides. We then cut these into the appropriate sizes and shapes – top panels, vamps, counters, shaft lining, vamp lining. The top pieces will have their patterns stitched on, then these pieces must be sewn together. The stitch that connects the bottoms to the tops is called a fitting stitch.

The front and back panels have to be put together at this point. The seam where those come together is called the side seam. It receives this designation because it is the one that follows the side of your calf down to your ankle, and the bottom of your foot on each side of the boot. This seam is done with the boots turned inside out, so that it is not visible from the outside once the boot is finished.

With the boot shell complete, we go to lasting. Lasting is the point where we take the mold (last) and commence shaping the boot around it and the insole. The last that you use determines the toe, width and exact size of the boot.

With the boot lasted, we staple the vamps (bottoms) to the insole. In the same place where these staples are, we sew the bottom welt on. The bottom welt is what will hold the front portion of the outsole on. It is the part you will see with the one or two rows of heavy stitching around the very front of the boot.

After the bottom welt stitching, we lay the shank, midsole and then the outsole. One trimming process, which we call rough rounding, takes us to the sole stitching. The name is pretty self-explanatory, but the sole stitch is the stitch that holds the outsole.

After sole stitching, we peg the shank into place. Those are the brass pegs that you see at the arch of the foot. After this, we take the last out of the boot. It has a hinge that allows for this. With the last out, we nail the heels on. There are seven annular threaded nails that hold each heel on.

With the heels, there are a handful of trimming and sanding stations that shape up all the edges around the heel and outsole.

With this done, the boots have a finish brushed onto the sole edges and heel. We use a clear finish, red-brown or dark brown finish or black finish.

Finally, the padded insole cushion is glued inside the boots and they go to a final checking station, where they are checked for protruding nails, discoloration, leathers that don’t match, missed stitches and many other hiccups. After that, they are boxed and either sent to our store in downtown Nocona or shipped directly to the store that’s shelves they will sit on until the day they are bought and worn.

Please also share other details of the process (how long it takes, how many people work on one pair of boots, etc.).

There are more than 100 individual steps that go into making a boot. We have anywhere from 50-60 employees pushing through 200-250 pairs, on any given workday. Our production boots normally take 3-4 weeks, from the time they are scheduled until they go into the box. They move much quicker than special order boots because all of their material we keep on hand, and they are normally boots that the employees have seen and built before.

As for the fit in general, certain people claim that certain brands fit them better than others, and that may be true. But, I personally, have worn many different brands and styles of boots and it’s comparable to buying any shoe. Get the size that fits, wear them for a while, and more often than not you’ll end up being just fine with them.

What are the signs of a quality pair of boots?

Material, more times than not gets overlooked, but it is one of the biggest signs of a well-made boot. Most well-made boots will have either a cowhide or goat upper, with some kind of full-grain leather vamp, like cowhide, bullhide or some kind of exotic hide. Many people will understand this, but more importantly you move onto the less obvious parts of the boot – like the lining. This part of the boot comes in contact most with the foot and lower part of the leg. Traditionally, you would use a full-grain cowhide or pig for the lining that gives it the breathability and comfort.

More and more companies are skipping this step and going with some kind of synthetic lining, which feels more like a cushion and doesn’t have a break-in process, but over time will come apart and give way to a very bad smell coming out of the boot. If you get deep into the anatomy of a boot, you want to look at the material of the shank. The shank is what goes in the arch of the foot to give it good form and support. Larger companies will use a steel shank that it much cheaper than the option we stick with – a fiberglass shank. If you ever heard a boot squeak, often you are hearing something going wrong with the shank. You can flip the boot over and look at the leather sole toward the heel; there should be some sort of line of nails. Lemonwood pegs are preferred over brass nails, but either can be used in a good quality boot.

What is the average price to pay for a pair of Fenoglio boots?

Non-exotics are normally around $200.00

Smooth ostrich- $225.00

Full quill ostrich- $400.00

Caiman- $500.00

Elephant- $350.00

Arapaima- $550.00

(Raw-material value plays a lot into the pricing of these.)

What are the logistics in buying the raw hides (no pun intended) for you?

Due to the fact that leather tanneries are so scarce in the U.S., we, along with most everyone in the industry, buy most of our non-exotic leathers and some other components from Mexico. (Mexico is a dominant producer in footwear; only 20% of the footwear in Mexico is imported.)

Non-exotic leather would be cowhide, bullhide, pig, goat or bison. Obviously, things that are native to the U.S.

I acquire exotic leathers mostly through dealers in the U.S., who warehouse said materials to save me the import and shipping costs. These would consist of ostrich, caiman, alligator, teju lizard, stingray, arapaima, elephant, python and rattlesnake. Some of these I may also get straight from the source. The python we get from Singapore; the ostrich from South Africa.

How long does it take if I order a personalized pair – from order date to delivery?

The time frame for personalized boots varies pretty significantly, depending on the time of year. Our busiest times are the holiday season (late October to December) and rodeo season (mid-May and April). If the order goes in during the summer or late spring, we quote 8-12 weeks for delivery; but if it is during one of the times stated previously, it could be 3 months or so.

Fenoglio Boot Co.

1606 West Pine St.

Nocona, TX 76255

940-825-3047

www.fenoglioboot.com

Photos Courtesy of Fenoglio Boot Co.

This article is originally published on www.shoptalk-magazine.com and re-published here with permission.