by Nick Pernokas

The 16-year-old bronc rider limped to the fence. He exited the arena and headed over to the stripping chute, loosening his borrowed chaps as he walked. He collected his bareback rigging and returned the “community” chaps to his friend who was about to ride. He reflected on how much simpler life would be if he had his own pair. “I was ate up with wanting to rodeo,” remembers Joey Jemison.

Joey Jemison and his friends were familiar faces around the stockyards and they had endlessly studied the gear that shops like Fincher’s, Ryon’s, Leddy’s and L. White’s displayed. They knew that L. White Saddlery had the coolest chaps if you were a young rough stock rider.

The reason was that L. White’s had a talented young saddle maker, Jim Plant, working for them. Jim had also ridden rough stock, steer wrestled and roped. He had taken Joey under his wing, coaching him on all the rodeo events and encouraging him to enter all of the events at the high school rodeos.

In 1971, Joey was in his junior year in high school and needed to find a job that he could work two days a week to satisfy his “distributive education” requirements. He decided that he could kill two birds with one stone if he was able to get a job at L. White’s. At the very least he could probably work off a pair of chaps, and get to hang out with Jim.

L. White’s hired Joey to work on the sales floor three days a week. After a couple of days, Joey asked Ms. White if he could help Jim Plant up in the saddle shop for free on the other three days. She went along with it.

“I was a shy, bashful kid and not much of a salesman,” says Joey. “After the second week Ms. White said that I could just stay up in the saddle shop if I wanted to.” Joey worked six days a week in the saddle shop for the rest of his junior year. The two days that he was paid for brought in $24.00. “I got to where I kind of liked what I was doing,” says Joey.

Late spring in Texas gets hot and Joey headed down to Ryon’s Saddle Shop to get a new straw hat. While he was there, Doug Loesch of Ryon’s, introduced Joey to Windy Ryon and asked Joey if he’d like to work at Ryon’s. Joey realized that he might get paid for every day and agreed on the condition that he wouldn’t start until the school year was over.

That summer Joey went to work in Ryon’s strap shop for $1.25 an hour. The early Seventies were the twilight era of the large saddle shops with an apprentice system. Eventually, an opening came up in the saddle shop and shop foreman Wilford Lewis moved Joey into it. “That’s where I really first began building saddles.”

By the time Joey was 18, he was building two saddles at a time and tooler, Mike Brisceno, would stamp them. Joey was paid $99.00 per saddle that he built. Mike made $67.50 for each saddle that he fully carved. The carving was laid out and drawn directly on the leather. One day, famed cowboy Phil Lyne came in the store, and Windy told Phil to pick out a saddle for himself from the saddles on the sales floor. The one that Phil picked was Joey’s.

By 1974, Windy Ryon had passed away and Wilford Lewis had left Ryon’s. A former Ryon’s saddle maker, Bud Connella - better known as Cajun, had opened his own shop down the street and was riding the wave of the booming cutting horse industry. Joey felt that things had changed at Ryon’s and he decided to move to Cajun’s. Joey liked Cajun personally, but felt that he was hard to work for. After a short stint there, Joey went back to Ryon’s.

When another saddle maker who had worked for Cajun, Calvin Allen, opened a saddle shop in Stephenville, Texas, he asked Joey to join him. In January 1975, Joey enrolled at Tarleton State University and worked in Calvin’s shop a few miles away. A year and a half later he moved to Graham, Texas, and went to work for Darrell Long at The Saddle Shed. In 1978, Joey went to work at Leddy’s in Fort Worth. In 1981, he opened his own shop in Byers, Texas. It was basically a one-man shop with a part-time tooler and a full-time strap goods man to help.

“I was six months or better behind on my saddles then, which sounds good , but the truth of the matter is that people don’t want to wait that long.”

By 1985, the oil bust was hurting the cutting horse business, and it hurt Joey’s business as well. Joey went back to Leddy’s. He decided to try running his own shop again in 1989. Joey was determined not to fall as far behind on his orders this time. Starting out in his garage in Fort Worth, he stockpiled more materials and hired Tink Odell to make saddles. Soon he hired more workers. Joey allowed them to put their names on his saddles, along with his.

“I didn’t want guys building saddles for me just to get a paycheck. Their name was on the line as well as mine. I felt like I got a better product.” Joey leased Jim Murray’s old shop in the stockyards when he outgrew the garage. In 1995, he moved his shop to its current location in Weatherford. He built both the 3500- square-foot shop, and the house, to blend in with the surrounding rolling hills dotted with live oaks.

Joey Jemison’s storefront showroom is the first thing you see through the front door. It’s filled with beautiful strap goods, purses, belts and saddles. Most of the building is dedicated to the saddle shop where these products are created though, and it’s filled with thoughtfully laid out work stations and machinery that let a small number of people create a surprisingly large quantity of high-end merchandise.

Joey Jemison’s storefront showroom is the first thing you see through the front door. It’s filled with beautiful strap goods, purses, belts and saddles. Most of the building is dedicated to the saddle shop where these products are created though, and it’s filled with thoughtfully laid out work stations and machinery that let a small number of people create a surprisingly large quantity of high-end merchandise.

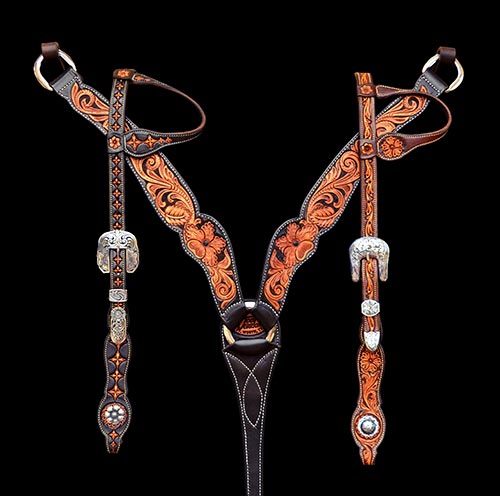

Joey has diversified over the years and offers many varied items that have a similar style and high quality carving. A two-tone dyed and antiqued color scheme has become the signature look on his products that unifies them on the display racks. His belts and strap goods are lined with English bridle leather. The carving varies from different floral patterns to unique geometric stamps. Even belts with the same flower have subtle differences in decorative cuts and stamping that let the customer know they’re getting a unique piece. Joey keeps an eye out for new stamps to add to his patterns.

“I gross more with my saddle business than any other item, but it’s the lowest profit margin. Saddles are a hard way to make a living.”

Joey has been long identified with cutting saddles, but he also builds reining and cow horse saddles. Other than horns, swells and some cosmetic differences, he feels that they are very similar. Part of this is that bloodlines of horses for these events overlap and many of the horses are built similarly. Joey’s base price for a rough out saddle is $4750.00.

At 63, Joey has seen many changes in cutting saddles. When Bob Moline built the original “Buster Welch” flat seat cutting saddle at Ryon’s, he started with an Association bronc saddle. It had a larger two rope dally horn and a two piece ground seat. Tree makers started grinding down the horn caps smaller and smaller until 1 ¼ - 1 ½-inch caps were the norm. Saddle makers started using one piece ground seats to make the seats board flat. The original cutting saddles had Arizona bars, and then Darrell Tidwell designed a thinner, narrower bar to make the flat seat feel narrower. Gradually, ground seats were raised in the front to create a deeper seat with a pocket. An 8-inch swell was the norm in the Seventies, but today an 8 ½-inch swell is. Occasionally, you see a 9-inch swell, but Joey thinks this is extreme. “In a cutting saddle, a little bit of pocket isn’t bad, but when you’re stuck in one spot, that’s not good.”

When Joey has a customer that wants a lot of rise in the front of the seat, he makes it drop off quickly so there’s still enough room to move in the back for cutting. Today, most of his customers just want a slight rise. The bars in his trees are patterned after the old Tidwell bars, but he thins the bar on the top of the back of the seat to let the rider sit lower in the seat.

Joey also builds a lot of chaps. He feels that there’s a real need for custom-made chaps right now, especially shotguns that fit properly. The chaps are his second highest grossing item.

Trade shows are an important part of Joey’s program, and while he has always gone to cuttings, these days he also goes to reining and reined cow horse events.

Joey’s wife, Connie, trained cutting horses until she had a serious wreck on a two year old. She decided that she should branch out into some other ventures, so she bought a laser. Today, Connie has become adept at using the laser in countless applications. She uses the laser to decorate the bottom of hat brims for custom hat manufacturer, Shorty’s Caboy Hattery. However the laser has found many uses in the leather shop. Perfect paper patterns can be made for new products, actual leather parts can be cut out, they can be tweaked and then they can be sent off to a die maker for extremely accurate dies. Logos and letters can be outlined on the leather with the laser, and then carved and stamped, producing a better result than tracing them. Even the hangers used to display belts with can be decorated with it. Joey also does some repair work and since he makes his own saddle trees, he also repairs broken trees. Joey fiberglass covers his own trees, which he feels produces a better, and longer lasting, saddle tree.

“If I had to go back to using rawhide trees, I’d probably quit building saddles.”

Joey feels that you get more variance in the thickness of the rawhide over the bar than you get with fiberglass. There is more moisture trapped on the wood with rawhide, and the strainer seat has to be nailed on in rawhide trees. This can create small cracks in the bars.

Today, one employee meticulously dyes the headstall pieces that he’s just stamped, while another works on some chaps. They have a tremendous amount of product in various stages of completion around them. Joey believes in having a good selection of the strap goods on hand. Although they are hand tooled in a variety of patterns, they all look just like the photos on his website. A lot of Joey’s business comes from the internet and he feels that the shopping trend now is towards instant gratification. Customers don’t want to wait for an item. Brick and mortar stores gave way to trade shows and now Joey feels that the shows are declining due to internet shopping. Joey and Connie get all this work done with only the two full-time employees in the shop, as well as two really good saddle makers who build saddles out of their homes.

“The only reason that I think that I have survived and done good is that I have changed. You look at what we’re doing and it doesn’t look like anything we used to do.” In another concession to the new millennium, Joey has put his saddle company in a separate corporation to limit his liability.

Today, Joey lives only about 40 miles from the old Fort Worth stockyards, but he’s come a long way from that kid with silver buckle dreams. And Joey did get that pair of chaps.

Find Joey Jemison Custom Leather in both our TACK and APPAREL sections to find more information.

This article was featured on Shop Talk Magazine and is published here with permission.